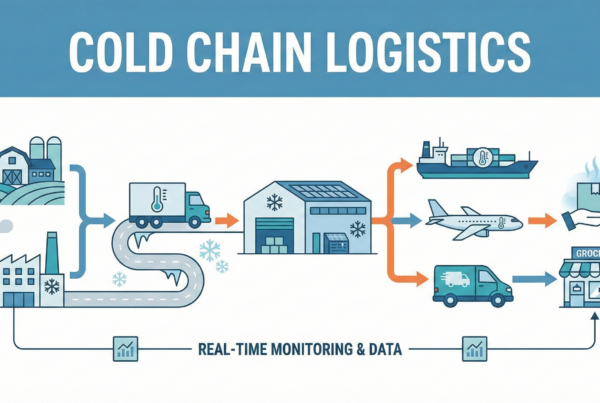

An effective cold chain is more than just refrigeration — it’s a carefully designed system that keeps perishable products safe, fresh, and compliant from origin to destination. Even small gaps can lead to spoilage, losses, or regulatory issues for companies moving food, pharmaceuticals, or high-value perishables.

At CFI, we know that designing an effective cold chain means building resilience at every step. Below are best practices to help you strengthen your infrastructure, protect your products, and maintain trust with your customers.

Best Practices for Cold Chain Design

- Map the Journey, Not Just the Storage

Cold chains are networks, not warehouses. Identify every touchpoint where temperature control could falter — from loading docks to cross-border transfers — and design safeguards into each stage. - Choose the Right Packaging

Insulated containers, gel packs, phase-change materials, and vacuum panels all help maintain stable conditions. Match packaging to product sensitivity, distance, and transit time. - Leverage Monitoring Technology

IoT sensors, data loggers, and GPS tracking give real-time visibility. Alerts on temperature deviations help prevent losses before they escalate. - Invest in Redundancy

Back-up power, spare reefer units, and multiple transport partners create resilience. Redundancy keeps shipments moving even when a single link fails. - Train Personnel Thoroughly

Human error is a significant risk in cold chain management. Provide consistent training so employees understand loading protocols, proper handling, and emergency steps. - Align with Compliance Standards

Certifications like HACCP, FDA/FSMA, and CFI’s own FreshChain program are essential. Standards ensure your operations meet regulatory requirements while inspiring customer confidence. - Plan for Last-Mile Delivery

The final stage is often the riskiest. Use insulated vehicles, timed delivery windows, and trained drivers to maintain cold integrity right to the customer’s door.

Why Cold Chain Resilience Matters

- Consumer safety depends on it, whether it’s preventing bacterial growth in food or protecting vaccine potency.

- Global trade demands it, with perishable exports relying on strict temperature control to cross borders smoothly.

- Your reputation rides on it, as a single breach in quality can mean lost customers and regulatory penalties.

CFI’s Approach

With decades of expertise in cold storage, transportation, and distribution, and backed by certifications like FreshChain, CFI designs cold chains that work in the real world.

Cold chain operations at LAX, SEA, JFK, MIA, ORD, IAH, BOS, SFO, ANC, DFW, ITO, KOA, LIH, HNL, OGG, YHZ, YVR, GDL, MEX, and global handoff points support a worldwide supply chain that demands both speed and accuracy. We’re not just transporting freight—we’re safeguarding value, freshness, and trust at every step. CFI integrates technology, compliance, and hands-on service to ensure perishables arrive exactly as promised: safe, fresh, and intact.

Connect with CFI today if you need a cold chain partner who builds resilience into every link.