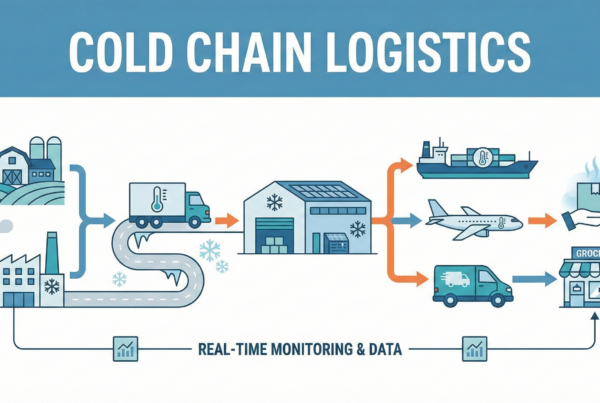

From the moment fresh berries are harvested in Watsonville to when sushi-grade tuna is plated in Las Vegas, the cold chain must remain uninterrupted. At CFI Perishables, maintaining cold chain integrity is not just about logistics—it’s a company-wide commitment rooted in precision, compliance, and care.

“Cool Chain as a Culture” powers every step in their handling of temperature-sensitive freight, ensuring quality from intake to handoff. Here’s how CFI contributes to that critical process:

1. Inbound Receipt: Start with the Right Temperature

Whether it’s fresh produce from California or floral imports from Ecuador, CFI’s role begins when the product reaches their facility—either from the shipper or picked up from the airport post-import.

- Temperature verification on receipt ensures products are within acceptable limits before entering their cold storage.

- Airport pickup for imports, followed by controlled transport to CFI’s facility, protects perishables during the first mile on U.S. soil.

- No USDA inspection delays on exports at CFI: Any inspection for protein or produce happens earlier—at the processing plant or farm—well before CFI ever sees the cargo.

2. Packaging: Shipper-Controlled, CFI-Verified

CFI does not repackage freight—but they do verify what arrives:

- Shippers provide packaging, which may include gel packs, dry ice, or vented cartons, depending on the product.

- CFI monitors and maintains temperatures from receipt to release using validated processes and storage protocols.

3. Transfers: Direct and Compliant

For air export, CFI doesn’t rely on third-party truckers for terminal drops.

- As a TSA-certified Indirect Air Carrier, CFI must handle the transfer of all export shipments to the airport using its own drivers.

- CFI-trained handlers, not general cargo staff, manage freight with expertise in sanitation, temperature control, and product-specific handling.

- International transfers (via air hubs such as AMS or NRT) occur airside or through temperature-controlled facilities, depending on the route and airline protocols.

4. 24/7 Monitoring: Cold Chain Visibility

Continuous visibility keeps perishables protected:

- Shipments are tracked with GPS and temperature loggers, allowing for real-time visibility while cargo is in CFI’s custody.

- Alerts for deviations help catch problems early—before quality is impacted.

- Monitoring devices continue tracking even after CFI hands off the freight, especially for international moves.

5. Handoff at Destination: When the Consignee Takes Control

CFI’s responsibility ends when the freight departs their facility or is handed off to the airline. For imports or domestic deliveries:

- CFI may transport between its own stations (e.g., Boston to New York or Anchorage to Seattle) but is not involved in international last-mile delivery.

- The consignee or their appointed carrier typically takes possession at the destination, often post-clearance (if international).

“Cool Chain as a Culture” in Action

What makes CFI stand out? Every handler, forklift driver, and export coordinator is trained to treat perishables with the urgency they deserve. It’s not about moving boxes—it’s about preserving freshness, shelf life, and food safety.

With cold chain hubs in key places like LAX, SEA, JFK, MIA, ORD, IAH, BOS, SFO, ANC, DFW, ITO, KOA, LIH, HNL, OGG, YHZ, YVR, GDL, MEX, and global handoff points, CFI is a trusted partner for clients who need reliable handling for time- and temperature-sensitive cargo. We’re not just transporting freight—we’re safeguarding value, freshness, and trust at every step.

Looking for a cold chain logistics provider that knows the science and the stakes? CFI doesn’t just move perishables—they protect them. Reach out today and safeguard your supply chain with proven expertise.